When embarking on a construction or DIY project, selecting the right materials is crucial for ensuring durability, efficiency, and overall success. Among the myriad of options available, Formply stands out as a top choice for builders and contractors alike. This versatile material, often used in formwork applications, offers numerous advantages that can greatly enhance the quality and longevity of any project. Here are five compelling reasons to consider Formply for your next endeavour.

1. Exceptional Durability

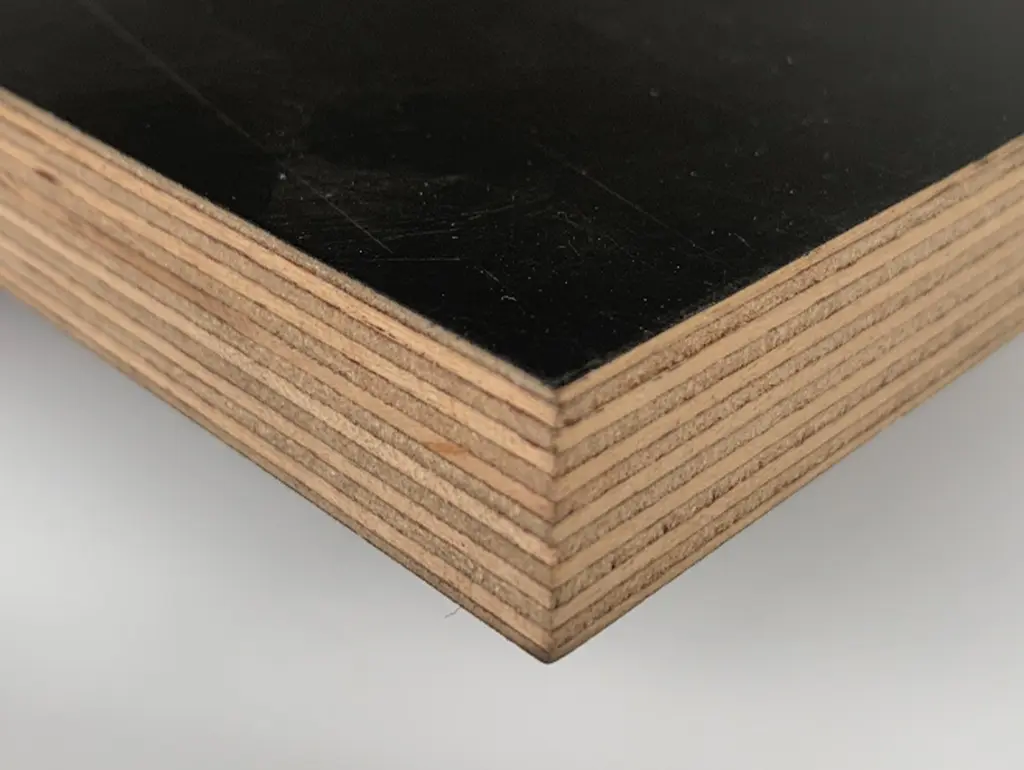

One of the most significant advantages of Formply is its remarkable durability. Made from high-quality plywood and treated with a phenolic resin, Formply is designed to withstand the rigours of construction environments. This treatment not only enhances its strength but also provides resistance to moisture and wear.

In summary, buy formply is a material that offers numerous advantages for construction and creative projects alike. Its exceptional durability, cost-effectiveness, versatility, environmental friendliness, and aesthetic appeal make it an ideal choice for builders and contractors. By choosing Formply for your next project, you not only ensure a high-quality outcome but also contribute to sustainable building practices.

Resistant to Environmental Factors

Formply is engineered to endure various environmental conditions, making it suitable for both indoor and outdoor applications. Whether exposed to rain, humidity, or extreme temperatures, Formply maintains its structural integrity, ensuring that your project remains on track without unexpected delays due to material failure. Its resistance to environmental factors is particularly beneficial in regions with unpredictable weather patterns, where traditional materials may falter under stress. The ability to perform consistently, regardless of the surroundings, makes Formply a reliable choice for contractors and builders alike.

Long Lifespan

Investing in Formply means investing in longevity. Its robust construction allows it to withstand repeated use, making it an ideal choice for formwork that may be reused multiple times. This not only saves money in the long run but also reduces waste, aligning with sustainable building practices. Furthermore, the longevity of Formply contributes to a reduction in the frequency of replacements, which can be a significant cost-saving factor for large-scale projects. With its ability to retain performance characteristics over time, Formply stands out as a cost-effective solution that meets the demands of modern construction while promoting environmental responsibility.

Learn more on: Why Formwork Plywood Is Key to Reliable Concrete Structures

Additionally, the manufacturing process of Formply is designed with sustainability in mind. By utilising renewable resources and adhering to eco-friendly practices, the production of Formply minimises its carbon footprint. This commitment to sustainability not only benefits the environment but also enhances the reputation of builders and contractors who choose to incorporate such materials into their projects. As the construction industry increasingly prioritises eco-conscious choices, Formply serves as a prime example of how durability and sustainability can go hand in hand, making it a forward-thinking option for contemporary building needs.

2. Cost-Effectiveness

While the initial cost of Formply may be slightly higher than other materials, its long-term benefits far outweigh the upfront investment. The durability and reusability of Formply lead to significant savings over time, making it a cost-effective choice for builders. In fact, many construction professionals have reported that the longevity of Formply can result in a lower total cost of ownership when compared to traditional materials, which often require more frequent replacement and can lead to unexpected expenses. Read more about durability on https://pubmed.ncbi.nlm.nih.gov/21696703/

Reduced Maintenance Costs

Formply requires minimal maintenance compared to other materials. Its resistance to damage from moisture and wear means that it will not need frequent replacements or repairs. This translates to lower maintenance costs, allowing project budgets to be allocated more efficiently. Furthermore, the ease of cleaning Formply surfaces contributes to its low upkeep requirements, making it an ideal choice for projects where hygiene and cleanliness are paramount, such as in food processing or healthcare facilities.

Efficiency in Project Execution

The reliability of Formply can also lead to faster project completion times. With fewer interruptions due to material failure or maintenance issues, builders can focus on completing the project on schedule. This efficiency can ultimately enhance profitability and client satisfaction. Additionally, the lightweight nature of Formply allows for easier handling and quicker installation, reducing labour costs and minimising the time spent on site. As a result, contractors can take on more projects within the same timeframe, further amplifying their potential revenue streams.

3. Versatility in Applications

Formply is incredibly versatile, making it suitable for a wide range of applications. Whether it’s for concrete formwork, flooring, or even furniture, Formply can adapt to various project requirements. This adaptability is one of the key reasons why architects and builders alike have embraced this material, as it allows for innovative designs without compromising on functionality.

Ideal for Concrete Formwork

One of the most common uses of Formply is in concrete formwork. Its smooth surface allows for a clean finish, while its strength ensures that it can hold the weight of wet concrete without warping or bending. This is crucial for achieving the desired structural integrity in any construction project. Additionally, Formply’s resistance to moisture and chemicals makes it an excellent choice for projects that require durability in harsh conditions, such as foundations or retaining walls. The longevity of Formply in these applications can significantly reduce maintenance costs over time, making it a wise investment for builders. To read more about resistance click here.

Creative Uses Beyond Construction

Beyond traditional construction applications, Formply is also gaining popularity in creative projects. Designers and craftsmen are increasingly using Formply for custom furniture, cabinetry, and even decorative wall panels. Its aesthetic appeal, combined with its durability, makes it a favourite among those looking to create unique, long-lasting pieces. Furthermore, the material can be easily cut, shaped, and finished, allowing for intricate designs that showcase the natural beauty of wood grain. This versatility has led to innovative uses in interior design, where Formply is often employed to create bespoke shelving units, stylish room dividers, and even artistic installations that blend functionality with visual interest. As sustainability becomes a more pressing concern, the use of Formply, which can be sourced from responsibly managed forests, aligns well with eco-friendly design principles, making it an even more attractive option for modern creators.

4. Environmentally Friendly Choice

In an age where sustainability is paramount, Formply presents an environmentally friendly option for builders and contractors. The manufacturing process of Formply involves using sustainable timber sources, which contributes to responsible forestry practices. This commitment to sustainability not only supports the preservation of natural habitats but also ensures that future generations can benefit from these vital resources. By choosing Formply, builders are making a conscious decision to support eco-friendly practices that have a lasting positive impact on the environment.

Recyclable Material

Formply is not only made from renewable resources, but it is also recyclable. At the end of its life cycle, Formply can be repurposed or recycled, reducing waste and minimising environmental impact. This aligns with the growing demand for eco-friendly building materials in the construction industry. Furthermore, the ability to recycle Formply means that it can be transformed into new products, thereby conserving energy and reducing the need for virgin materials. This circular approach to material use is becoming increasingly important as the construction sector seeks to innovate and adapt to more sustainable practices.

Reduction of Carbon Footprint

Choosing Formply can also contribute to a reduced carbon footprint for construction projects. By opting for materials that are sustainably sourced and recyclable, builders can play a part in combating climate change and promoting a healthier planet. Additionally, the lightweight nature of Formply can lead to reduced transportation emissions, as less energy is required to move these materials to construction sites. This aspect not only enhances the overall sustainability of a project but also helps builders meet stringent environmental regulations and standards that are becoming commonplace in the industry.

5. Enhanced Aesthetics

Formply not only excels in functionality but also offers aesthetic benefits. Its smooth, clean surface is visually appealing, making it suitable for projects where appearance matters.

Perfect for Visible Applications

In projects where the formwork will be visible, such as exposed concrete walls, Formply provides a superior finish. The smooth surface ensures that the final product looks professional and polished, enhancing the overall aesthetic of the structure. This is particularly important in modern architectural designs, where the interplay of materials can significantly influence the visual impact of a building. The seamless integration of Formply into such designs not only elevates the aesthetic quality but also reflects a commitment to craftsmanship and attention to detail.

Customisation Options

Formply can also be easily customised to meet specific design requirements. Whether it’s cutting to size or applying finishes, Formply can be tailored to suit the unique needs of any project, allowing for greater creative freedom. This adaptability extends to various finishes that can be applied, including stains, paints, and textures, enabling designers to achieve a specific look that aligns with their vision. Furthermore, the ability to incorporate branding elements or unique patterns into the Formply can transform a standard construction project into a bespoke masterpiece, making it an ideal choice for commercial spaces that aim to leave a lasting impression on visitors.

Conclusion

As the construction industry continues to evolve, selecting materials that combine performance with environmental responsibility will become increasingly important. Formply stands out as a material that meets these criteria, making it a wise investment for any project. Whether you are a seasoned builder or a DIY enthusiast, considering Formply could be the key to achieving outstanding results.